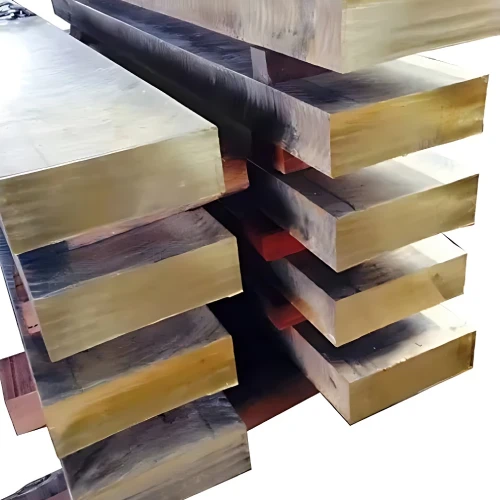

C90500. also known as gunmetal, is a copper alloy belonging to the red brass family. It offers a good

combination of strength, wear resistance, and corrosion resistance, making it suitable for various

industrial applications.

Table: Key Properties of C90500

| Property |

Description |

| Chemical Composition |

- Primarily Copper (Cu): 88-90% <br> - Tin (Sn): 4-6% <br> - Lead (Pb): Up to 0.5%

(sometimes lead-free variants exist) <br> - Zinc (Zn): Up to 1% <br> - Other (Fe,

etc.): Trace amounts

|

| Mechanical Properties |

- Good tensile and yield strength <br> - Good wear resistance <br> - Good

machinability (especially lead-containing variants) <br> - Good corrosion resistance

|

| Common Brands (By Country) |

- Europe: CuSn4Pb1Zn1 [Europe] <br> - US: Gunmetal, Leaded Red Brass

|

Important Note: The presence of lead (Pb) in C90500 can vary. Some manufacturers offer

lead-free variants. Always check the specific datasheet for the material you're considering.

Common Questions and Answers:

What are the typical applications of C90500?

C90500 finds use in various industries due to its well-rounded properties:

Gears: Its strength and wear resistance make it suitable for gears, particularly for

lower-load applications.

Bearings and bushings: C90500 can be used for bearings and bushings in applications with

moderate loads.

Wear plates and liners: Industrial machinery can benefit from C90500's wear resistance

for wear plates and liners.

Marine applications: Due to its decent corrosion resistance, C90500 can be found in some

marine environments (depending on severity).

How does the presence of lead affect C90500?

Similar to C90700. lead can improve machinability in C90500 but raises environmental and health concerns.

Lead-free variants are available, offering similar properties but slightly lower machinability.

What are some limitations of C90500?

While C90500 offers many advantages, there are a few limitations to consider:

Cost: Compared to some other copper alloys, C90500 can be slightly more expensive.

Welding: Welding C90500 requires specific techniques to prevent cracking. Consulting a

welding professional is recommended.

Not ideal for high temperatures: The mechanical properties of C90500 can diminish at

elevated temperatures.

Important Note: Always consult with a material engineer or supplier to identify the most

suitable copper alloy for your specific application considering factors like strength, wear resistance,

corrosion resistance, machinability, lead content (regulations), cost, and operating temperature.