C91100 is a copper alloy belonging to the tin bronze family. However, compared to other copper alloys

previously discussed, information readily available online about C91100 is limited. Here's what we can

gather based on the limited sources found:

Possible Chemical Composition:

Primarily Copper (Cu): Likely high copper content with a significant amount.

Tin (Sn): Potentially between 4% and 8% based on the naming convention of similar tin bronzes.

Other elements (Fe, Zn, Pb): Trace amounts possible.

Potential Properties:

Likely good castability due to the copper content.

Possible good machinability depending on the specific composition (uncertain about lead content).

Moderate strength and wear resistance based on the tin content (specific values unknown).

Possible Applications (educated guesses based on similar alloys):

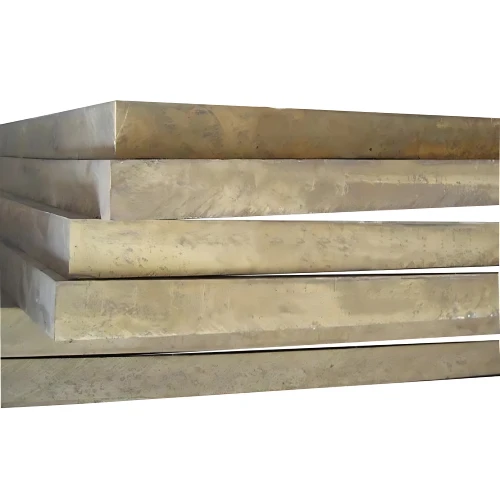

Bearings and bushings in low to moderate load applications.

Wear plates and liners in industrial machinery.

Decorative castings due to potential good castability (depending on the application).

Table: Key Properties of C91100 (Limited Information)

| Property |

Description |

| Chemical Composition |

Limited information available. Likely high copper content with tin (4-8%) and trace amounts of

other elements.

|

| Mechanical Properties |

Moderate strength and wear resistance (specific values unknown). Possible good castability and

machinability (depending on lead content - unknown).

|

| Common Brands (By Country) |

Information on specific brands not readily available. |

Important Note: Due to the limited information available online, relying solely on this

introduction for C91100 is not recommended.

Common Questions and Answers:

What are the specific properties of C91100?

Unfortunately, without consulting a material datasheet or contacting a copper alloy supplier, pinpointing

the exact properties of C91100 is difficult. The composition information found online is speculative based

on the naming convention of similar alloys.

What are the applications of C91100?

Similar to the properties, specific applications are uncertain. Based on the tin content, C91100 might be

suitable for bearings, bushings, and wear plates in low to moderate load applications. Decorative castings

could also be a possibility due to potential good castability. However, confirmation is needed from a

reliable source.

Are there alternative copper alloys with better information available?

Yes, several copper alloys with well-documented properties can be considered depending on your specific

needs:

C91300: Offers good castability for low-stress components.

C91700: High-tin bronze with excellent strength, wear resistance, and good corrosion

resistance (lead-free).

Leaded tin bronzes (e.g., C92200. C93200): While not ideal due to environmental concerns,

some leaded bronzes offer a balance between castability, strength, and wear resistance (consult

regulations).

Important Note: Always consult with a material engineer or supplier to identify the most

suitable copper alloy for your specific application considering factors like desired properties,

castability, and regulatory compliance. They can provide you with datasheets and recommendations based on

your needs.