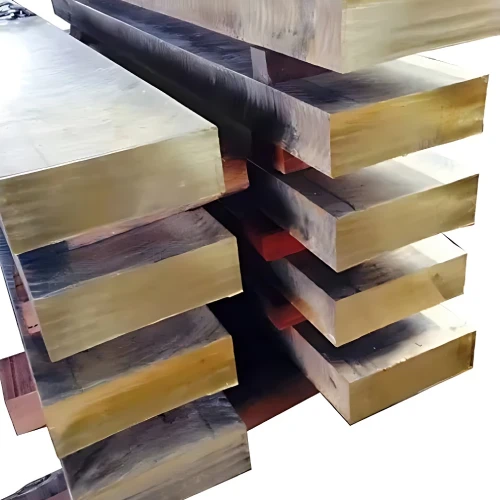

C17200, also known as Beryllium Copper Alloy 25, is a high-performance copper alloy renowned for its

exceptional strength, hardness, and electrical conductivity. This alloy is widely used in applications

requiring precise mechanical properties combined with high electrical performance.

Chemical Composition

C17200 is primarily composed of the following elements:

| Element |

Percentage (%) |

| Copper (Cu) |

98.1 - 99.1 |

| Beryllium (Be) |

1.80 - 2.0 |

| Cobalt (Co) |

0.20 - 0.60 |

| Others |

Balance |

Mechanical Properties

C17200 exhibits excellent mechanical properties, making it suitable for a wide range of demanding

applications:

| Property |

Value |

| Tensile Strength |

1240 - 1380 MPa |

| Yield Strength |

1100 - 1240 MPa |

| Elongation |

1 - 3% |

| Hardness (Rockwell C) |

38 - 45 |

| Electrical Conductivity |

22 - 25% IACS (International Annealed Copper Standard) |

| Density |

8.26 g/cm³ |

Corresponding Country's Brand

C17200 is recognized under different brands in various countries. Here are some equivalents:

| Country |

Brand Name |

| USA |

Beryllium Copper Alloy 25 |

| UK |

CW101C |

| Germany |

CuBe2 |

| Japan |

C1720 |

| China |

QBe2.0 |

Common Questions and Answers

1. What are the primary advantages of using C17200 in industrial applications?

Answer: C17200 offers a unique combination of high strength, excellent hardness, and good

electrical conductivity. It is particularly valued in applications requiring precise mechanical properties

and high electrical performance, such as in aerospace, electronics, and tooling industries.

2. Can C17200 be easily machined or welded?

Answer: C17200 can be machined using conventional methods suitable for copper alloys.

However, its high strength and hardness require sharp tools and proper machining techniques. Welding C17200

is possible but requires precautions due to the presence of beryllium, which requires proper ventilation and

safety measures.

3. What are the typical applications of C17200?

Answer: C17200 is commonly used in applications such as electrical connectors, springs,

switches, and components requiring high strength, hardness, and electrical conductivity. Its properties make

it suitable for use in aerospace components, precision instruments, and high-performance electrical

contacts.

Summary Table

| Aspect |

Details |

| Chemical Composition |

Cu (98.1-99.1%), Be (1.80-2.0%), Co (0.20-0.60%), Others (Balance) |

| Mechanical Properties |

Tensile Strength: 1240-1380 MPa, Yield Strength: 1100-1240 MPa, Elongation: 1-3%, Hardness:

38-45 Rockwell C, Electrical Conductivity: 22-25% IACS, Density: 8.26 g/cm³

|

| Country Brands |

USA: Beryllium Copper Alloy 25, UK: CW101C, Germany: CuBe2, Japan: C1720, China: QBe2.0 |

| Applications |

Electrical connectors, springs, switches, aerospace components, precision instruments,

high-performance electrical contacts

|

C17200 Beryllium Copper Alloy 25 is highly valued for its exceptional combination of strength, hardness, and

electrical conductivity, making it a preferred choice in critical industrial applications.