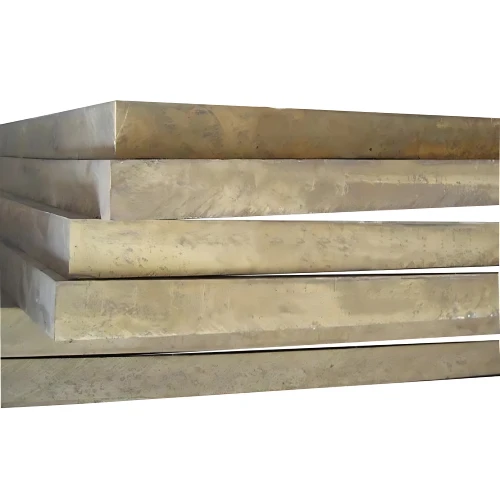

C95800: High-Strength Nickel-Aluminum Bronze for Wear Resistance and Corrosion Resistance

C95800 is a copper alloy belonging to the nickel-aluminum bronze family. It's known for its exceptional

combination of high strength, excellent wear resistance, and good corrosion resistance. Here's a look at

its key characteristics:

Table: Key Properties of C95800

| Property |

Description |

| Chemical Composition |

- Primarily Copper (Cu): Minimum 99.5% (Sum of Cu and named elements) <br> - Nickel (Ni):

Up to 4% <br> - Aluminum (Al): 4-6% <br> - Iron (Fe): Content shall not exceed

Nickel content <br> - Other (Fe, Zn, etc.): Trace amounts

|

| Mechanical Properties |

- High tensile and yield strength <br> - Excellent wear resistance <br> - Good

machinability <br> - Good corrosion resistance

|

| Common Brands (By Country) |

- Europe: CuAl9Ni5Fe4 [Europe] <br> - US: Nickel-Aluminum Bronze |

Important Note: Brand names might vary depending on the supplier.

Common Questions and Answers:

What are the typical applications of C95800?

C95800 finds use in various industries due to its well-rounded properties:

Gears: High-strength gears, particularly for medium- to high-load applications, can be made

from C95800.

Bearings and bushings: In applications with demanding loads, C95800 is a suitable choice

for bearings and bushings.

Wear plates and liners: Industrial machinery can benefit from C95800's wear resistance

for wear plates and liners.

Marine applications: While not ideal for constantly submerged environments due to potential

for dezincification, C95800 can be used for some marine hardware due to its good corrosion resistance.

How does C95800 compare to other copper alloys?

C95800 offers several advantages:

Excellent combination of properties: It provides a balance of high strength, wear

resistance, and good corrosion resistance.

Good machinability: Compared to some other high-strength copper alloys, C95800 offers good

machinability.

Are there alternatives to C95800?

Depending on the specific application requirements, some alternative copper alloys can be considered:

Silicon bronzes (e.g., C65620): Offer good corrosion resistance but might have lower

strength.

High-tin bronzes (e.g., C93700): Excellent wear resistance but might be more expensive and

have lower strength compared to C95800.

Important Note: Always consult with a material engineer or supplier to identify the most

suitable copper alloy for your specific application considering factors like strength, wear resistance,

corrosion resistance, machinability, and cost. Be aware of potential dezincification concerns in saltwater

environments.